111 years old and still up to date

The conductor system: an invention that continues to have a significant impact on industry to this day

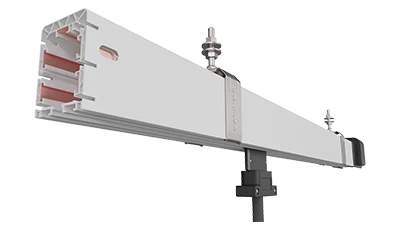

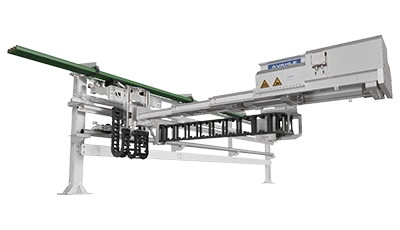

Paul Vahle is not a man who is content with the status quo. As plant manager of the Dortmund iron and steelworks Hoesch AG, he was extremely annoyed at the beginning of the 1910s that production was repeatedly brought to a halt because electrical machines failed due to a short circuit. This was caused by the open round copper cables that were used to supply the plants with power in the early years of electrification. Particularly in the case of moving equipment such as cranes, the live cables regularly come into unintentional contact with each other, overloading the systems. It's a problem that keeps the Dortmund man busy even after he's off duty. So in his spare time, he came up with a solution without further ado. It proved to be so convincing that it is still in use today - 111 years after Vahle patented it: the conductor rail.

After the Industrial Revolution in the mid-19th century, electrification provided the next developmental impetus for the economy, and a huge one at that. After the large companies had already replaced coal and steam as energy sources with electrical energy in the first decades of the 20th century, the small and medium-sized companies were now following suit bit by bit. Paul Vahle, who is not only a resourceful inventor but also has courage and business acumen, quickly recognizes the value of his invention. Without much advance preparation, but with a promising patent in his pocket, he put all his eggs in one basket and on April 9, 1912, founded his own company, VAHLE OHG, based in Dortmund-Brackel.

It soon became apparent that the risk was worthwhile. The company grows and prospers year after year. When the inventor of the conductor rail died in 1926, his wife Helene took over the management of the now 14-year-old, well-running company. In the meantime, production had reached its limits, so that in 1929 additional factory buildings had to be rented in Dortmund-Brackel. At this time, Helene Vahle was already being actively supported in the management of the company by her son Paul Werner, who finally took over the family business in 1932.

The turmoil of the Second World War, which rages from September 1939, does not leave VAHLE untouched. Paul Werner was drafted into military service and in 1945 became a prisoner of war, from which he did not return to Dortmund until four years later. And again it was a woman, this time Paul Werner's wife Maria, who successfully kept the company on course and expanded it. In 1936, the company already had more than 30 employees.

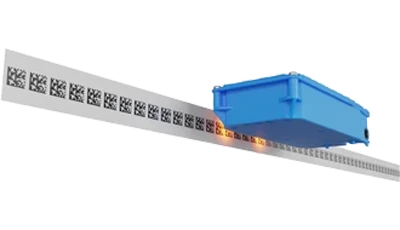

VAHLE then benefits strongly from the economic upswing of the post-war period: The turnover multiplies within a few years, while the number of employees climbs to several hundred. VAHLE also expands spatially and buys a piece of land on Westicker Straße in Kamen, where the headquarters are still located today. In the 1970s and 1980s, the company develops innovative and new products such as the light metal rail or conductor rails for electric monorail systems and thus proves that it has not lost any of the innovative spirit of the company founder and name giver over the years. Towards the end of the millennium, VAHLE then designed a system for inductive energy transmission for moving applications in materials handling technology - a technology that has long since been used not only in industry, for example to supply power to automated guided vehicles, but also in everyday life, for example to charge smartphones.

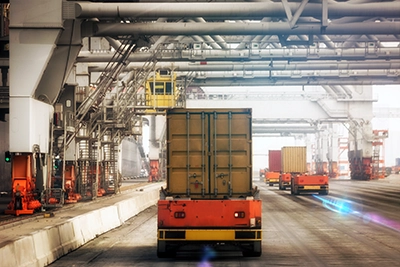

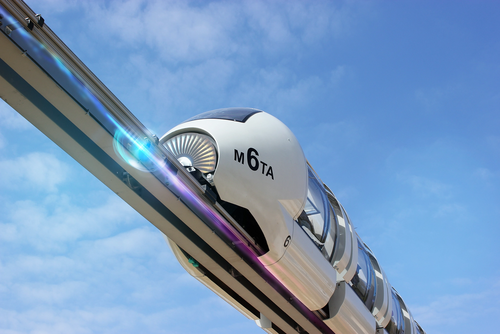

Today, 111 years after its founding, Paul Vahle GmbH & Co. KG, with around 850 employees, is one of the world's leading manufacturers of high-performance power, data transmission and automation systems and implements major international projects. Among other things, the company participated in the 1980s in the research project for the Transrapid magnetic levitation train, which has been hovering over VAHLE conductor rails in Shanghai since 2001. The most impressive project in which the Kamen-based company is involved as a partner, however, is in Dubai: the AIN Dubai Ferris wheel, which at a height of 260 meters is the tallest and largest in the world. Custom-made busbar systems reliably supply the 48 luxury cabins and the 65,000 LEDs of the Ferris wheel with power and prevent damage caused by lightning strikes. At many ports, too, nothing works without VAHLE's power and data transmission systems. Among other things, the Kamen-based company electrified and automated the Port of Felixstowe, Great Britain's busiest container port. The conversion of the facilities into so-called Green Ports are probably the most visible examples of VAHLE's commitment to sustainability, making tangible CO2 reductions possible worldwide.

The Kamen-based company also underlines its ambitions to make industrial power supply more sustainable through its involvement in numerous research and funding projects to develop DC busbars - a technology that has the potential to revolutionize industrial power supply once again. In this context, as consortium leader of the "effiDCent" joint research project, the company has developed a system for DC-fed rails that resembles a paradigm shift in industrial power supply and saves more than ten percent energy during operation.

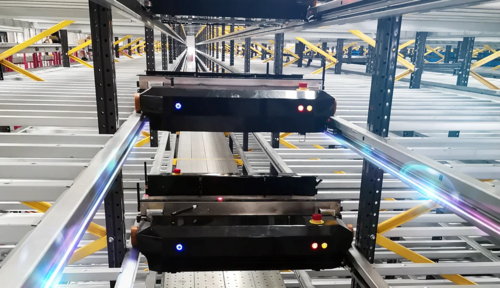

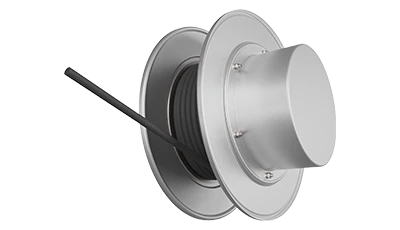

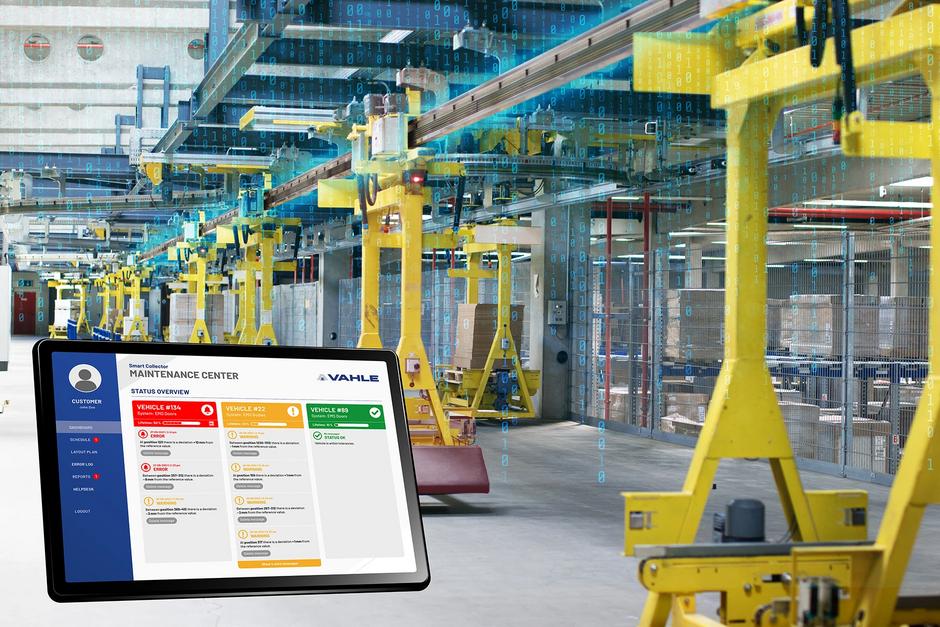

With the Smart Collector, the world's first intelligent current collector, the Kamen-based company also proves that it has not lost its inventive spirit. The Smart Collector is able to collect analysis data on the condition of the busbars as well as the entire plant in parallel with the operation of the plant. Thus, it detects foreseeable malfunctions, prevents unplanned downtimes, and thus ensures a smooth production process.

"VAHLE has always been an 'enabler', driving the industrial revolution with its products and initiating countless developments," emphasizes Achim Dries, CEO of the VAHLE Group. "This way of thinking and the claim to constantly develop ourselves further are still firmly anchored in the company DNA. Our spirit of innovation remains unbroken after 111 years and continues to be our driving force." Taking up customer demands and translating them into efficient, sustainable and safe processes - that is the maxim of the Kamen-based company, both yesterday and today. And nothing will change in the future.