- Downloads

- Customer Hub

-

Exhibition

-

Choose your language:

Industries

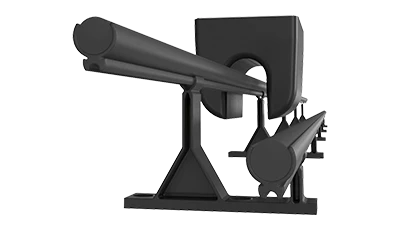

Individual solutions for heavy loads

Cranes are used in many industries. Steel producers, recycling yards and companies from the construction industry VAHLE offers reliable systems for energy and data transmission.

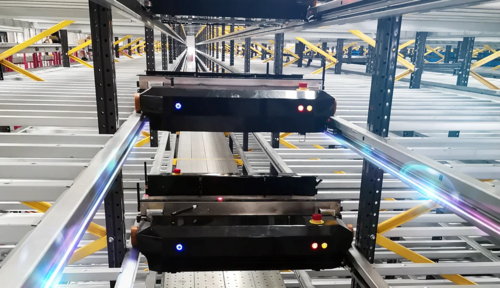

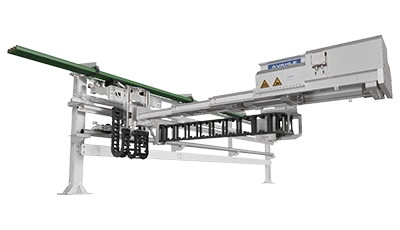

Automated conveyor technology in the internal flow of goods

Increasing production rates, high throughput volumes and short delivery times require partially or fully automated intralogistics.

Innovative solutions for flexible production processes

Adaptable manufacturing processes are the key to the greatest possible efficiency in vehicle production. VAHLE solutions for energy and data transmission make a significant contribution to this.

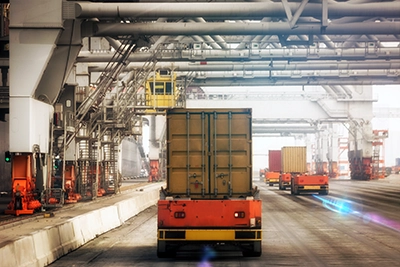

Innovative solutions for the ports of tomorrow

Zero emission is the requirement for the port of the future. With the solutions for energy and data transmission from VAHLE, port operators are getting closer to this goal.

Intelligent solutions for the rides of the future

The amusement, leisure and adventure sectors are often at the cutting-edge of the industry. That's why many ride builders and manufactures rely on VAHLE to provide roller coaster and ride passengers with increasingly extraordinary experiences.

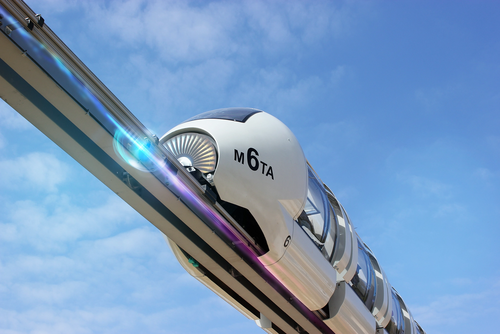

Automated transport systems for the mobility of the future

Streetcars, sky trains or rolling sidewalks are the future of resource-saving mobility. Many manufacturers rely on components from VAHLE for the design.

Innovative solutions for special mobile applications

Stadium roofs, waste incineration plants, facade elevators: Mobile industrial applications are used in many areas. VAHLE offers various special solutions for reliable energy supply and data communication.

Products

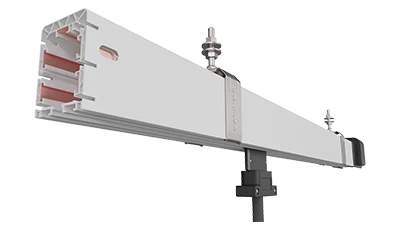

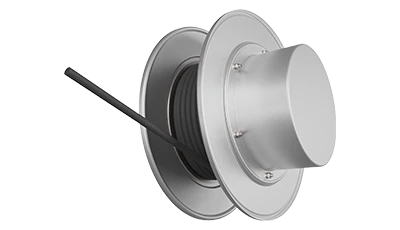

Energy transmission: reliable, efficient and flexible

Without energy, there is no movement. To perform their tasks reliably, mobile industrial applications need electrical power. Our vPOWER solutions offer the right transmission system for every requirement.

Data communication: fast, flexible and secure

Advancing digitization requires the transmission of ever greater volumes of data. Our vCOM solutions ensure reliable data communication for the control of automated conveyor systems at all times.

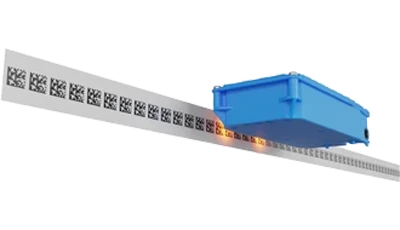

Positioning: robust, flexible and precise

Modern manufacturing requires automated conveyor systems that can be positioned with extreme precision. The prerequisites for this are created by our robust vPOS solutions, which are available with both magnetic and optical processes.

Control: mobile, scalable and efficient

Automation is shaping modern production processes more than ever. Numerous mobile conveyor units must be reliably controlled. With our versatile vDRIVE solutions, this can be achieved flexibly and with optimized performance.

System solutions: Everything from a single source

With our holistic system solutions, we offer a perfectly coordinated product combination of power transmission, data communication, positioning and control for a wide range of applications.

Services

VAHLE offers a wide range of services and support, including installation and commissioning, maintenance and repair, spare parts management and training. We are also available to serve as a general contractor for your project, if required.

Company

Who are we? Where do we come from? And where is the journey going? On our company pages you can find out everything about the VAHLE Group and its history, current events and successful customer stories. And of course there is also information here about where to find us and how to reach us.

Career

Take a look behind the scenes of a family-owned company. In our career section, you can find out everything about everyday working life and job profiles at the VAHLE Group, our training and further education opportunities, and current vacancies. And don't be shy: We are always looking for new, motivated colleagues!