Know today what will happen tomorrow: VAHLE hosts webinar on predictive maintenance

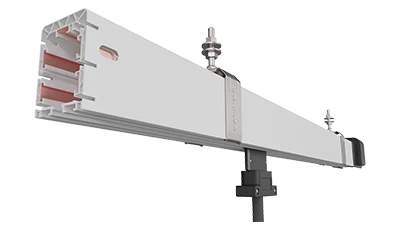

This becomes possible with the predictive maintenance tool for busbar systems - the Smart Collector. Join us for the free webinar on October 26, 11:00 am!

Paul Vahle GmbH & Co. KG is hosting a webinar on predictive maintenance under the motto "Smart Collector - know today what will happen tomorrow" on October 26 (Thursday) at 11 am. With the free online event, the world's leading provider of energy and data transmission systems for mobile applications will offer deep insights into its smart collector system. The innovative predictive maintenance tool enables plant operators to prevent unplanned production downtime and make the manufacturing process more worry-free. The 30-minute webinar will be held in German by VAHLE Product Manager Jessica Genz. All interested parties can register now and here to register free of charge.

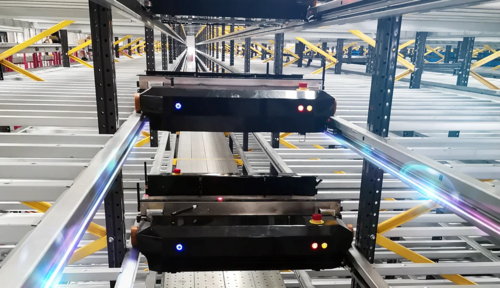

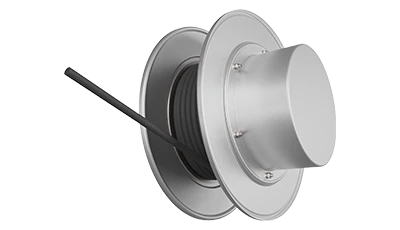

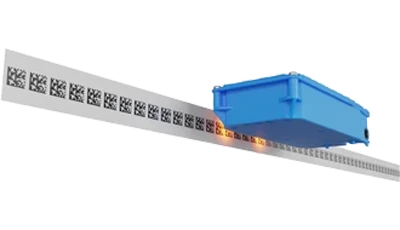

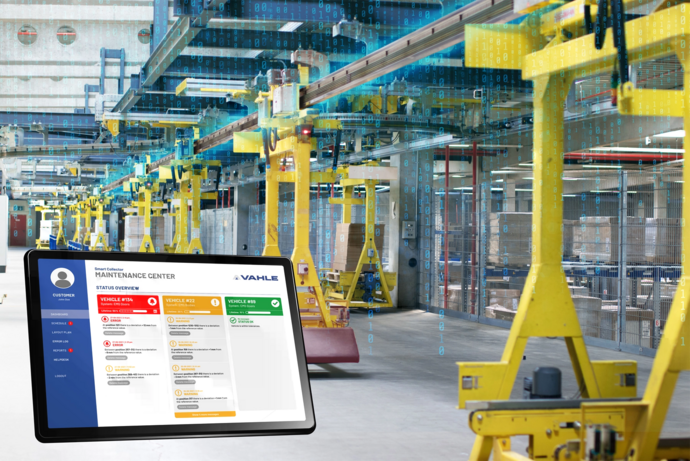

"Predictive maintenance is of utmost importance to all equipment operators as it prevents unplanned downtime, reduces operating costs and extends equipment life," says VAHLE Product Manager Jessica Genz. With the Smart Collector, VAHLE delivers the world's first predictive maintenance tool for conductor rail systems for this purpose, enabling precise monitoring and analysis of conductor rails in real time. "With this, we are taking the maintenance of manufacturing and conveyor systems to a new level. Unplanned plant downtime is finally a thing of the past with the Smart Collector," said Genz.

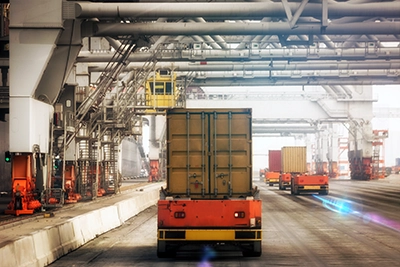

During the webinar, the product manager will not only explain in detail how the Smart Collector works, but also show how it helps to improve manufacturing and conveying systems. "Especially during peak times, when goods need to be moved around the clock, production downtime can quickly become expensive for companies. With our predictive maintenance solution, maintenance can be planned, and maintenance and service are optimized," explains Genz.

Participants can expect a comprehensive introduction to the system and its many possible applications. In addition, practical examples will be given and experiences from industry experts will be shared to illustrate the advantages of the innovative solution. Only recently, VAHLE had equipped the Smart Collector with new functions. Version 1.2, for example, is now also IDAA-capable, a method in which the entire system is permanently measured and analyzed for its condition in real time, parallel to the system operation.

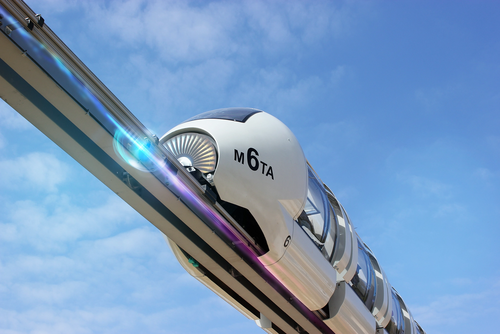

Anyone interested can take a close look at the Smart Collector at the VAHLE booth at the SPS in Nuremberg from November 14 to 16 in Hall 4, Booth 336, where intelligent current collectors will be seen live in action on an electric monorail system. In addition, a VAHLE team of experts led by Jessica Genz will be on hand to answer questions and present more information about the solutions.

Participation in the webinar is free of charge, but the content provided offers considerable added value for participants and their plants. Interested parties should register now here and register. Don't miss this exclusive insight into the future of maintenance technology.

To register simply click here!

Further information about VAHLE at: https://www.vahle.de