VAHLE presents extended functions of the Smart Collector at SPS

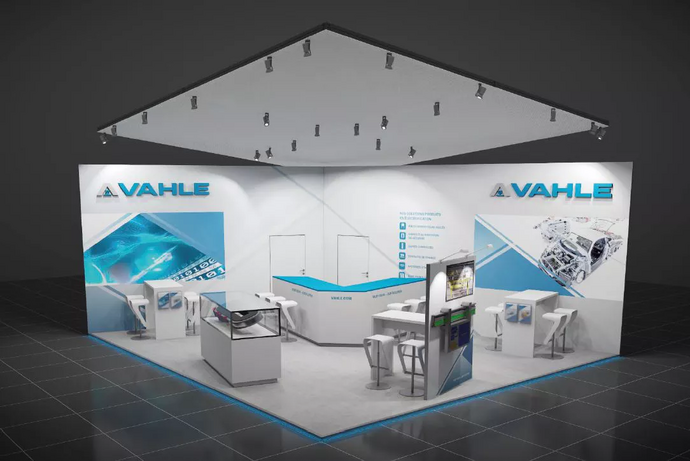

VAHLE at the SPS in Nuremberg - Smart Collector to be seen live in action for the first time on electric monorail system at booth #336 in hall 4.

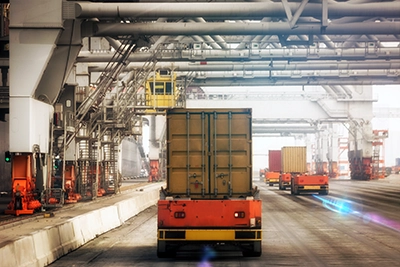

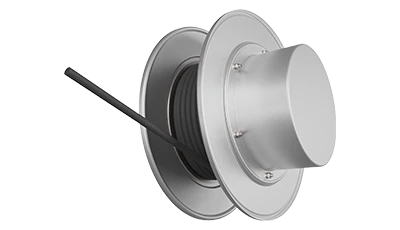

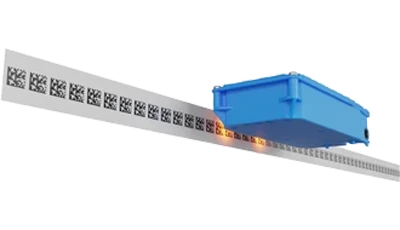

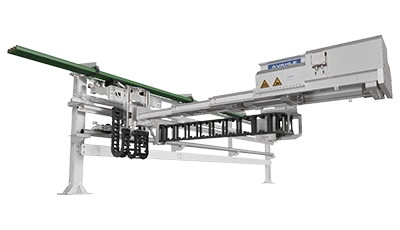

Paul Vahle GmbH & Co. KG will be exhibiting several upgrades to its Smart Collector at this year's SPS (Smart Production Solutions), which will be held in Nuremberg from November 14 to 16. Among other things, the Kamen-based system provider has recently equipped its globally unique intelligent current collector system with a thermal sensor. This makes it possible to record temperatures on the busbar in order to localize possible hotspots at an early stage. In addition, the phase distances of the predictive maintenance tool have been extended so that it can now also be used in high-bay warehouses and sorting systems. For the first time, trade fair guests will also have the opportunity to see the Smart Collector live in action on a large electric overhead conveyor. At the VAHLE booth in Hall 4, Booth 336, they will also learn all about the latest product features and upgrades first-hand.

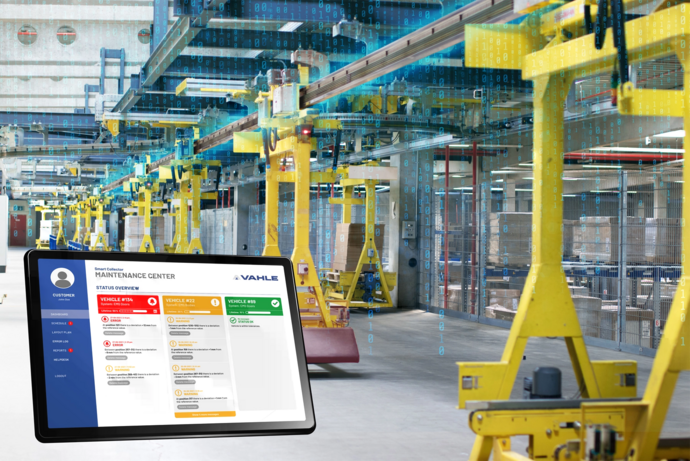

"With the recently implemented improvements, we can present a Smart Collector at SPS that is even more powerful and at the same time more versatile. In the predictive maintenance approach, which is an integral part of our system, we see the key to the future of industrial automation," says VAHLE Product Manager Jessica Genz. The innovative solution for powering mobile equipment makes it possible to prevent unplanned production downtime and make the manufacturing process more worry-free.

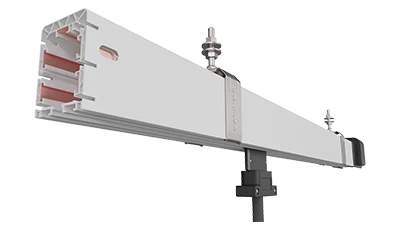

Only recently, VAHLE equipped the Smart Collector with new functions and made it IDAA-capable, among other things. A method in which the entire plant is permanently measured in real time parallel to system operation and analyzed for its condition. Now the intelligent current collector has received further upgrades - in the form of a thermal sensor that continuously measures the temperatures of the conductor rail during travel. In this way, assembly errors or defects, for example at transitions or poorly contacted joints, can be detected at an early stage.

The use of the thermal sensor can thus significantly increase the safety and efficiency of installations. "There is already a slot for the thermal sensor on our main unit, so customers do not need to purchase new hardware components or replace existing parts," explains Genz. The main unit analyzes the data from the thermal sensor in real time and transmits a warning message to the data center as soon as it detects thermal peaks. Analogous to the already familiar motion data messages, this message is then displayed in a traffic light system for the user. "And the best thing about it is that customers who purchase the software package in the early bird concept by the end of 2025 will not incur any additional costs for this high-quality enhancement," the product manager continues.

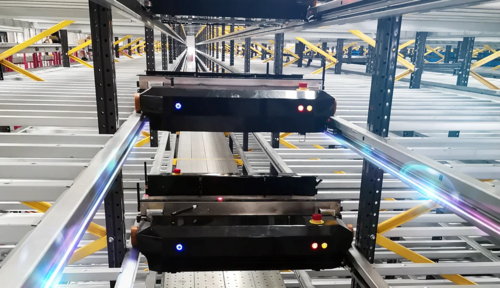

Another new feature is the Smart Collector's expanded range of applications. With immediate effect, it can also be used in areas such as high-bay warehouses and sorting systems.Furthermore, by extending the phase spacing, the predictive maintenance tool can now also monitor systems with a phase spacing of 18 mm and 26 mm, such as those found in VAHLE's VKS and U20 conductor rail systems.

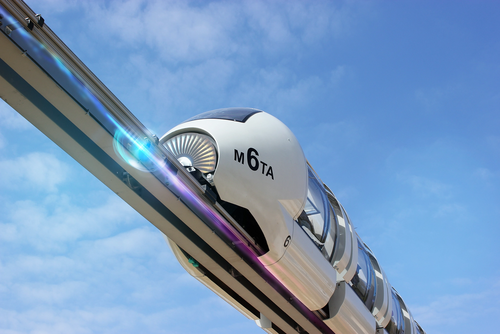

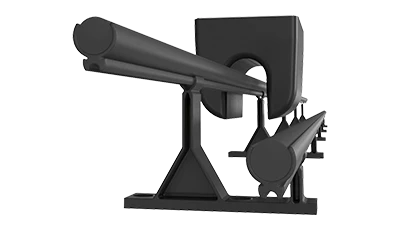

VAHLE also has news to offer outside of the product portfolio. This year, for example, the VAHLE trade fair stand has a completely new look. For the first time, the leading system supplier for mobile industrial applications is installing an electric monorail, which can be used to present the Smart Collector live and in action. Visitors to the trade fair will thus have the opportunity to experience the innovative technology and its advantages up close. For those who would like to get to know the Smart Collector before the trade fair, VAHLE is offering an expert webinar entitled "VAHLE Smart Collector: Knowing today what will happen tomorrow".

The webinar will take place on October 26 at 11 a.m. and will last 30 minutes.

Interested parties can register free of charge using the following registration link: link.vahle.de/seidabei

Further information about VAHLE at: https://www.vahle.de