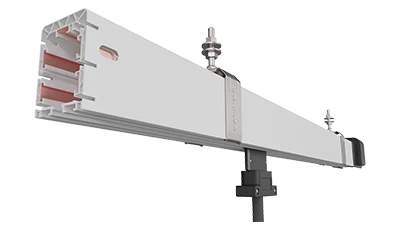

New features for the world's first intelligent current collector

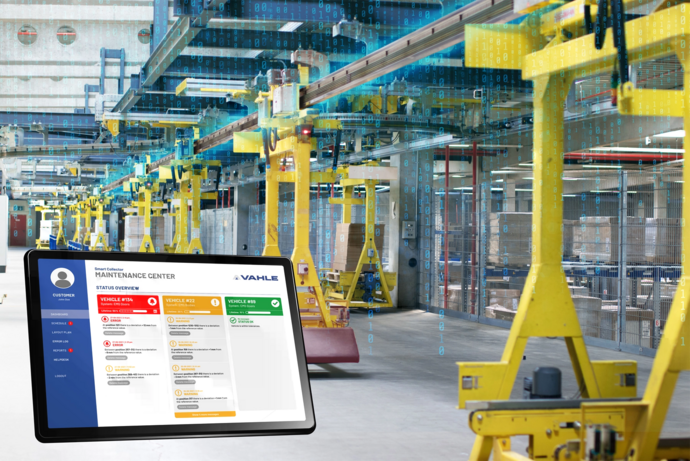

Smart Collector version 1.2 now available. The new automatic wear detection enables more accurate predictions and makes maintenance even more efficient thanks to IDA analysis.

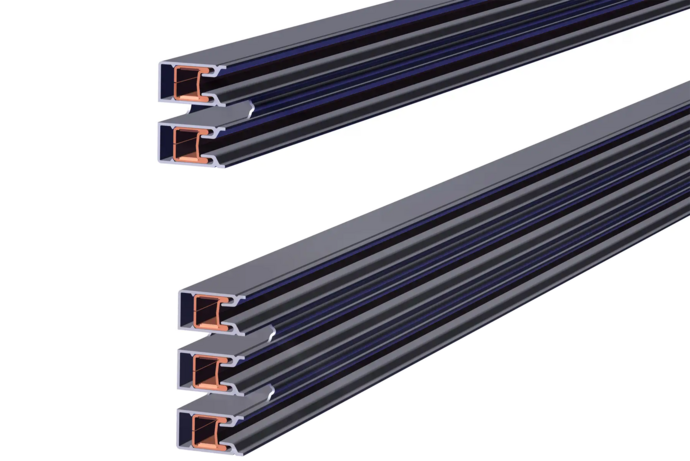

Paul Vahle GmbH & Co. KG is equipping its globally unique Smart Collector intelligent current collector system with new functions. Following a comprehensive release to version 1.2, the innovative product is now also IDAA-capable. The abbreviation stands for Intelligent Dynamic Anomaly Analysis, a method in which the entire system is permanently measured and analyzed for its condition in real time, parallel to system operation. In this way, anomalies are recorded even more precisely and signs of wear are detected automatically. At the same time, the methodology forms the foundation for the future use of machine learning methods, which can be used to determine the probability of occurrence for certain scenarios and events with great accuracy. VAHLE has also given the system's user interface a complete overhaul.

"With the update for the Smart Collector, we are setting a new milestone in the development of our maintenance tool. With the IDA analysis, wear is now automatically detected in addition to anomalies. In conjunction with an expanded data structure and additional zoom functions, users now have even more precise analysis and maintenance options," says VAHLE Product Manager Jessica Genz, describing the improvements that come with the new functions.

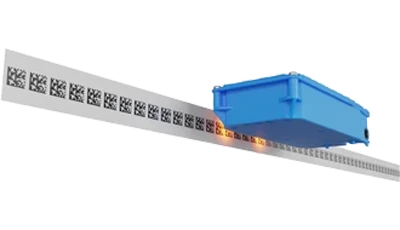

The basis for this is a new algorithm, which the Kamen-based system provider is using for the first time ever with the Smart Collector. The software update makes it possible to detect the smallest anomalies with centimeter precision in real time across the entire plant. In combination with even more accurate comparison values, the precision in terms of analysis and planning increases considerably. Genz: "Maintenance staff see the results at an early stage and can take the appropriate measures even before a plant failure occurs. Downtimes are thus minimized and the service life of the plant is extended." At the same time, the new algorithm provides a solid foundation for future developments - including machine learning.

Another new feature brought by the release is the expansion of motion detection. In addition to stroke movements, the system now displays deflection data. "This additional information improves error analysis enormously and enables the user to react at an early stage. This prevents subsequent faults, which in turn has a positive effect on the service life of the system," says the product manager. In addition, the Smart Collector now offers the option of assigning permanently collected data to the rail system with millimeter precision using the ZOOM function. This means that even the smallest defects can be investigated without having to immediately commission a maintenance team to carry out an on-site inspection. "This function makes both fault analysis and the targeted planning of maintenance measures considerably more efficient," says Genz.

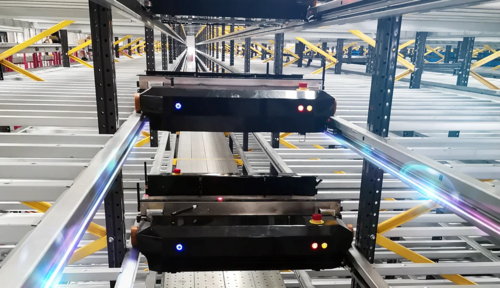

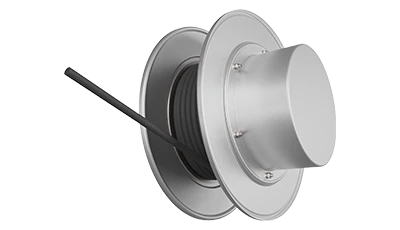

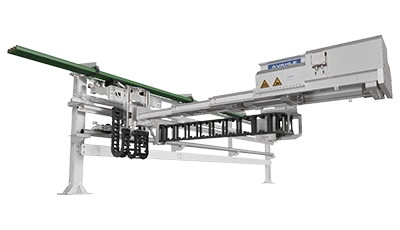

Smart Collector Release 1.2 is available immediately worldwide. "With this update, we are following our core idea of further developing the solution in close coordination with our customers," explains Genz. Various sensors can be connected to the system. As a result, all relevant information is displayed in one dashboard. "We analyze the specific problems and requirements of each customer to find the right setting of sensors and data together with them." Basically, the Smart Collector system not only enables tracking of the conductor rails themselves, but of all movements that are transmitted to the sensor. For example, it detects when Vulcan rollers wear out, as this causes the pantograph to lower, or vibrations on the trolley.

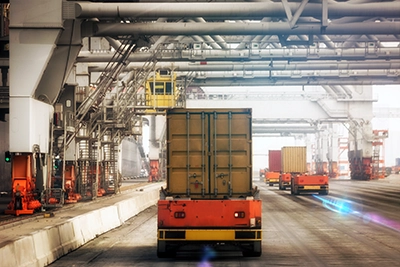

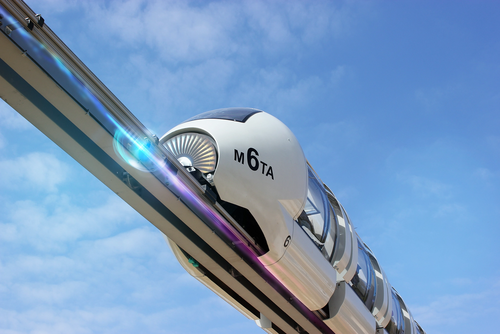

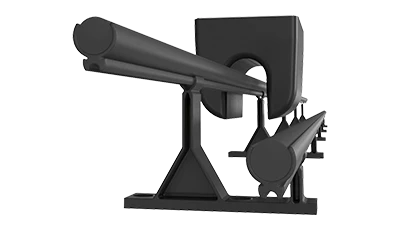

In Germany, VAHLE's Predictive Maintenance Tool is already successfully in use. In addition, the intelligent pantograph, which was specially developed for electric monorail systems and stacker cranes, is also being implemented step by step in other countries such as France, Italy, the USA and India. The focus here is primarily on use in the automotive industry, intralogistics and the sorting sector. Further upgrades and improvements are planned for the current year. The focus here is on integrating new sensors and expanding the tool for various applications to further increase efficiency and performance. "Our medium-term goal is a fully autonomous smart collector system," summarizes Genz.