VAHLE initiates paradigm shift in industrial power supply

VAHLE develops DC-fed conductor system with very high energy saving potential. This project was supported by the European Union and the state of North Rhine-Westphalia.

Paul Vahle GmbH & Co. KG has successfully completed the effiDCent joint research project, which aimed to increase energy efficiency and sustainability in industry by using direct current instead of the usual alternating current. Together with the Technical University of Dortmund, the Technical University of Ostwestfalen-Lippe, Condensator Dominit GmbH, and E-T-A Elektrotechnische Apparate GmbH, the Kamen-based technology pioneer has been conducting research since 2019 on more efficient energy transmission using a DC-based conductor system. VAHLE acted as consortium leader in this project. The conversion from alternating current (AC) to direct current (DC) results in an energy efficiency increase of more than 10 percent. At the same time, the resources required for the production of DC-based conductor systems are significantly lower compared to conventional systems. For example, copper requirements are reduced by up to 50 percent. The funding project was supported by the European Union and the state of North Rhine-Westphalia.

"The energy turnaround is a crucial building block for the transformation of our society toward sustainability. This is precisely the direction we are aiming in with the effiDCent research project, the result of which will be nothing less than a paradigm shift in industrial power supply," says Achim Dries, CEO of the VAHLE Group. The naming of the project is based on a combination of "efficient" and the abbreviation "DC", which stands for direct current.

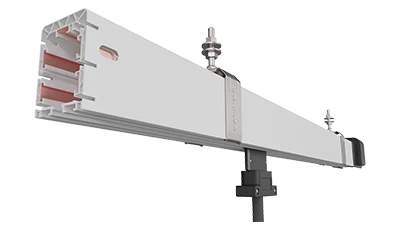

Development of DC-powered conductor systems

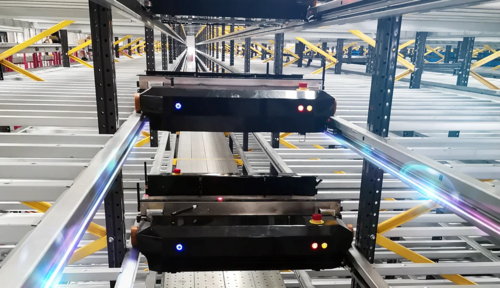

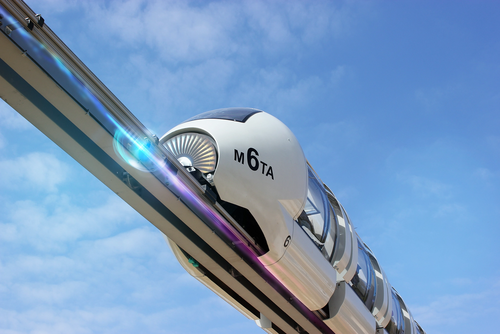

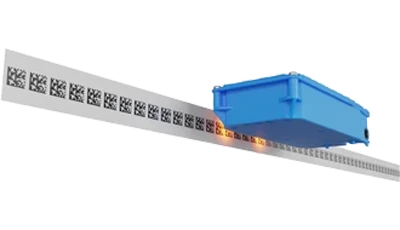

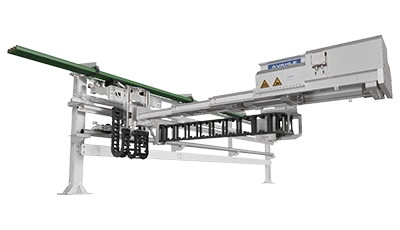

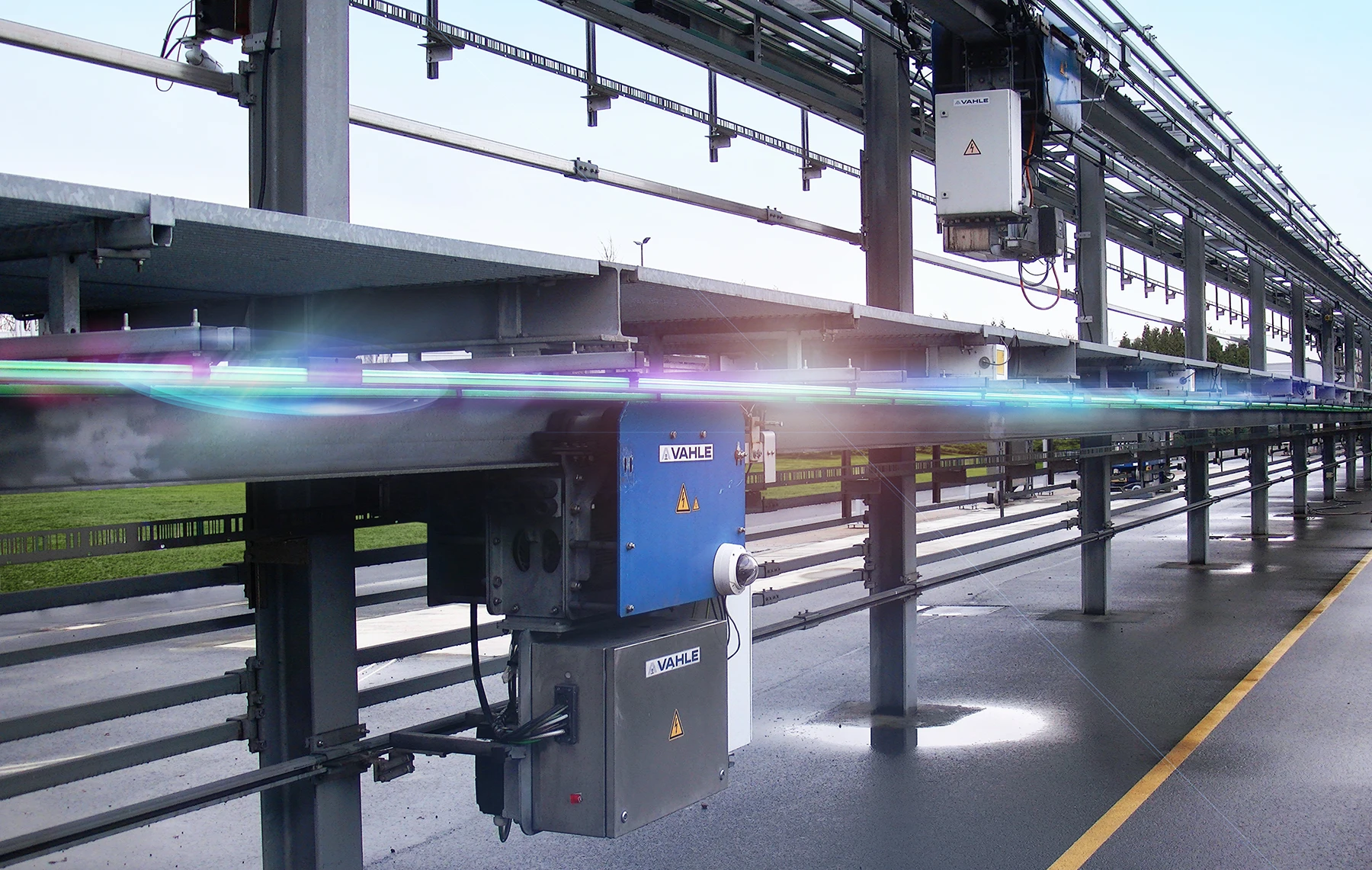

Together with its partners, the Kamen-based system provider for mobile industrial applications has spent the past three years developing a DC-powered system consisting of a highly efficient rectifier, the conductor system, intelligent energy storage units for recuperation, and safety devices. The aim was to significantly increase energy efficiency in manufacturing and production lines and minimize grid-related production downtime, thus optimizing the entire manufacturing process. Incidentally, the project partners broke new technical ground with the integration of intelligent energy storage systems and buffer capacitors distributed along the line.

On the one hand, the switch from AC to DC voltage allows a significant reduction in the material used and, on the other, promises high energy savings. In contrast to AC, the power factor of the motors or the inverters is not a factor, so the current load on the line is considerably lower. Accordingly, the copper requirement of a busbar can be significantly reduced not only by saving one pole but also by reducing the cross-section.

High potential for energy savings

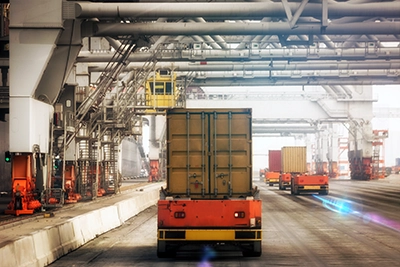

For industry, according to Dries, the switch to DC technology is a major step toward CO₂-neutral industrial production. Until now, the three-phase 400-volt AC voltage used as standard there has meant that a separate rectifier is needed for each vehicle, which is eliminated by a central DC supply. Eliminating the rectifier saves a lossy component in the overall system, which has a positive effect on overall efficiency and thus on energy consumption.

In addition, DC technology has numerous other advantages that help to create a modern and intelligent industrial power supply network. For example, systems for generating and storing energy such as photovoltaic systems and batteries can be integrated without any problems, since they basically operate with DC voltage. Braking energy can be stored directly and fully utilized without lossy conversion to alternating current. Another plus point is the high system availability provided by the use of storage: buffer batteries enable DC systems to continue operating without interruption. This means that there is no need for an expensive uninterruptible power supply (UPS). Additional investments for mains filtering and compensation are also eliminated. Built-in intelligent energy storage systems absorb load peaks caused by acceleration processes, so that the electrical connected load can be reduced, thus relieving the AC networks.

Funding from the European Union and the state of North Rhine-Westphalia

As part of the research project, an 80-meter DC test facility was commissioned in parallel with an existing AC facility. When using DC, an energy saving of more than 10 % could be demonstrated. VAHLE was responsible for the consortium management, the system design, the simulation and the construction of the test plant. TH OWL was responsible for the construction of the highly efficient feeder, with a 35 to 40 percent higher power factor compared to a standard rectifier.

The TU Dortmund University is responsible for researching the intelligent energy storage system for absorbing the braking energy. The use of braking energy by means of intelligent storage increases the efficiency of the overall system. This was made possible by the use of efficient energy storage devices, so-called ultracaps, which can store the braking energy for a short time and then release it again in a controlled manner. Due to the high inrush currents, it is difficult to switch on DC systems safely. For this reason, a protection and precharging concept tailored to DC applications was developed with ETA Elektronische Apparate GmbH.

With its participation in the research project, VAHLE is further expanding its position as a pioneer and technology leader in the field of direct current technology.

The company would also like to expressly thank the European Union and the State of North Rhine-Westphalia for their support of the project. Further thanks for the good cooperation go to the project management organization Jülich.

The effiDCent project at a glance:

- Research project focus: Development of a DC-powered busbar for industrial production lines.

- Project partners: Paul Vahle GmbH & Co. KG (consortium leader), Dortmund University of Technology, Ostwestfalen-Lippe University of Applied Sciences, Condensator Dominit GmbH and E-T-A Elektrotechnische Apparate GmbH (associated).

- Project duration: July 2019 to June 2022

- The project executing organization is Forschungszentrum Jülich PTJ.

- This project was funded by the European Union and the State of North Rhine-Westphalia.