VAHLE launches the world's first intelligent current collector on the market

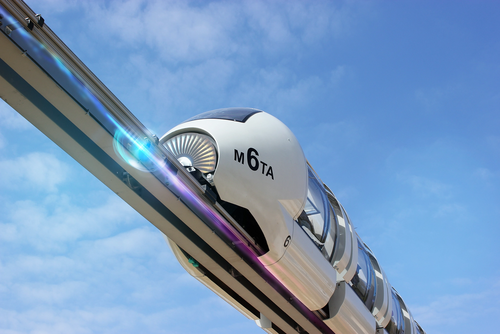

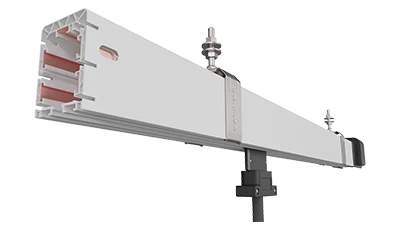

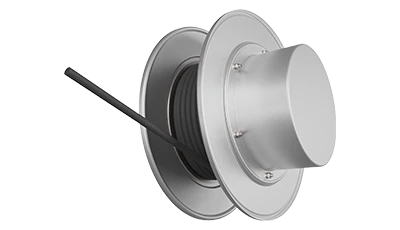

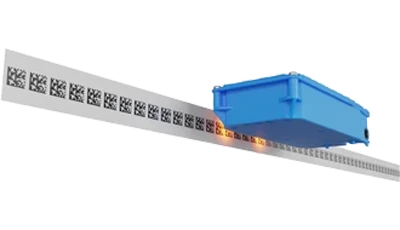

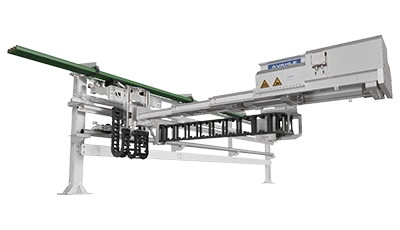

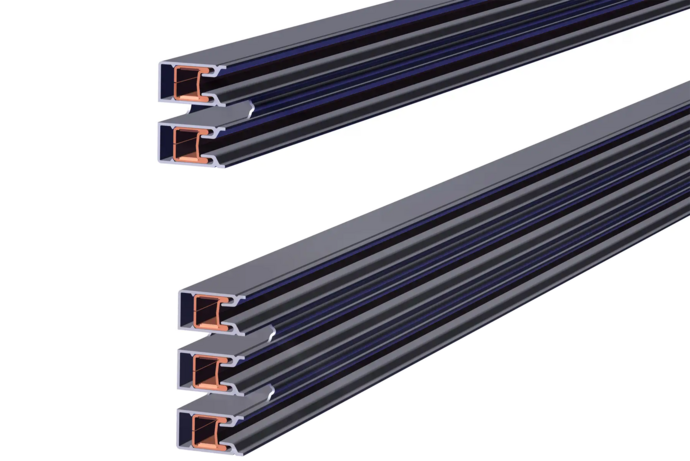

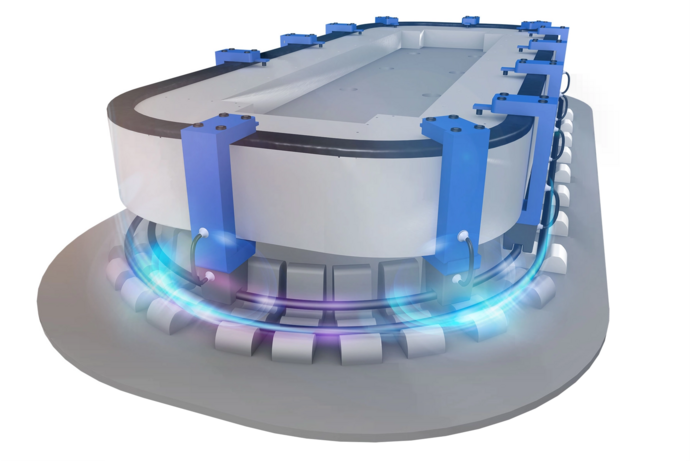

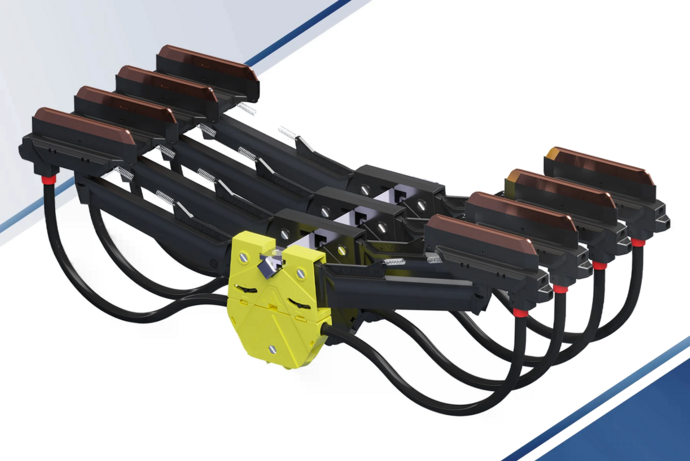

Paul Vahle GmbH & Co. KG has developed the Smart Collector, an intelligent current collector. The innovative product collects analysis data on the condition of the conductor systems and their components during operation. This is unique in this form on the market. Based on the values determined, the plug-and-play solution makes it possible to detect signs of wear or emerging faults at an early stage and to reduce unplanned downtime to a minimum.

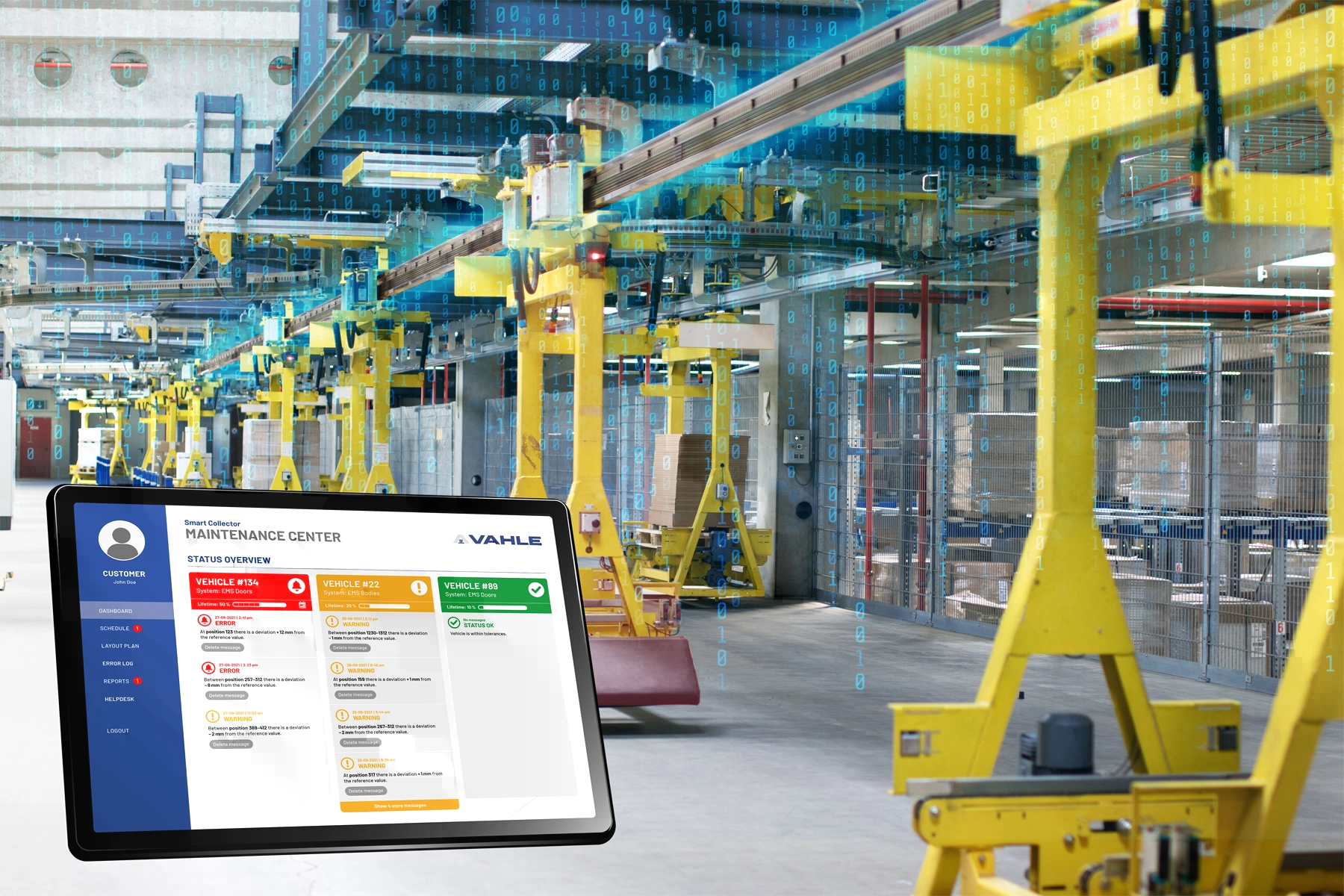

"Flexible systems and high plant availability are the be-all and end-all for modern production processes. Accurate knowledge of the condition of the equipment is an important prerequisite for this," says Jessica Genz, product manager at Paul Vahle GmbH & Co. KG. After all, failures and malfunctions cost a lot of time and therefore also money. "To ensure continuous monitoring and detect faults at an early stage, we have now developed the world's first intelligent conductor system monitoring system," says Genz.

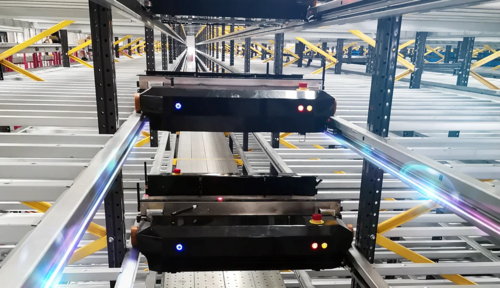

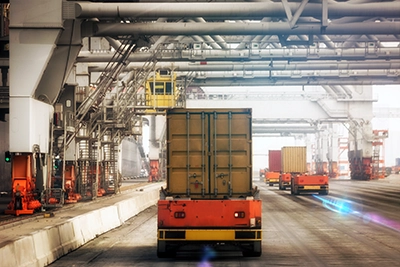

The Smart Collector has special sensor technology that detects the movements of the individual current collectors. In combination with a positioning system, movement parameters and any track anomalies are assigned with position accuracy and can thus be remedied in a targeted manner. "In addition to the alignment to the rail and the contact pressure, the Smart Collector calculates a wear forecast for the individual collectors based on the stroke and deflection movements," explains the product manager. The Smart Collector can be integrated into both new and existing installations and can, of course, be combined with existing technology.

The data is processed by the control unit, analyzed and transmitted to an ISO 27001-certified data center. This also enables the use of a remote helpdesk. "This allows us to detect anomalies at an early stage, determine the optimum time for maintenance and avoid routine inspections. This not only increases the service life of the equipment, but also reduces costs in the long term," says Genz. Required spare parts can then be ordered "just in time" via the VAHLE Customer Hub and no longer have to be kept in stock in large quantities.

"We are very proud to present the world's first intelligent current collector system on the market and thus make our customers' processes even more efficient and safe," says a delighted Achim Dries, Managing Director of Paul Vahle GmbH & Co. KG.

Currently, three pilot plants at well-known industrial companies are being equipped with the Smart Collector.

Further information about the Smart Collector can be found at: https://smartCollector.vahle.de