Engineering marvel: Floating ferry 2.0

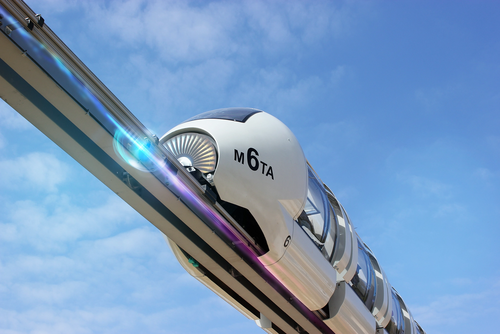

The centerpiece of the Rendsburg High Bridge is returning: Since March 2022, the unique floating ferry has once again been crossing the Kiel Canal. In January 2016, the unusual means of transport was irreparably damaged in a collision with a freighter, so that operations were suspended. The construction of a new ferry was a challenge. The counterpart should visually resemble the original, but at the same time be equipped with modern technology for energy and data transmission. This task was taken up by Paul VAHLE GmbH & Co. KG. The Kamen-based system provider for mobile industrial applications gave the floating ferry a technical update.

There are only eight floating ferries in the world. One of them is located in Schleswig-Holstein, attached below the historic railroad bridge that connects Rendsburg north of the canal with Osterrönfeld in the south. And that is exactly what makes the Rendsburg suspension ferry so unique. First put into operation in 1913, the old model crossed the canal for over 100 years. The new floating ferry now continues this tradition - thanks to Paul VAHLE GmbH & Co KG, which has breathed new life into the landmark. For commuters and tourists, who had to put up with long detours during the operational breakdown, it is now once again possible to cross the canal on a direct route with the suspension ferry after a standstill of almost six years.

Rising high with VAHLE technology

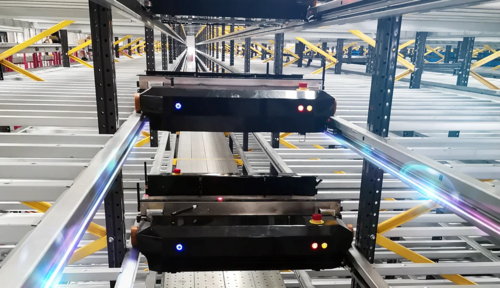

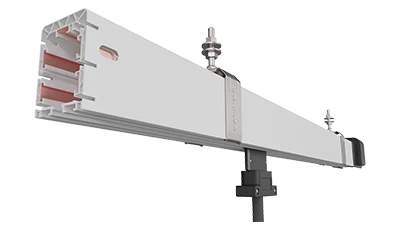

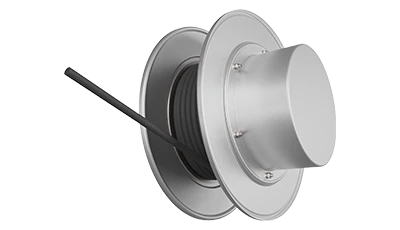

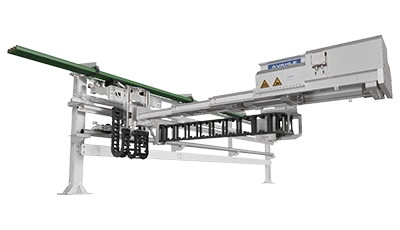

The suspension ferry transports pedestrians, cyclists and motorists across the Kiel Canal. Even though it is a marvel of technology, the ferry does not float, of course. Instead, it hangs on twelve steel cables under the bridge girder. For this purpose, VAHLE installed 135-meter-long, 5-pole U35 conductor system with a conductor cross-section of 200 square millimeters on each side of the bridge, which supply power to four 30-kilowatt electric motors.

"The installation was extremely challenging because we had to work at night under a full track closure," says Achim Dries, managing director at Paul Vahle GmbH & Co. KG. A track excavator was used to spread the material, which weighed several tons, on the bridge and attach it via a movable scaffold - at a height of 50 meters. "This was no easy task for our fitters. Anyone who is afraid of heights was out of place here," laughs Dries. To ensure that the ferry can "float" without malfunctions even in winter, VAHLE equipped the conductor system with additional heating conductors.

Video surveillance and predictive maintenance for smooth ferry operation

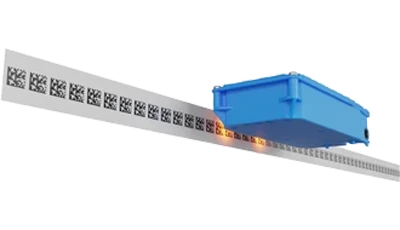

In order to prevent consequential accidents like the one in 2016 in the future, the ferry offers more safety for personnel and passengers. For this purpose, VAHLE has installed the SMGX data communication system, which ensures continuous video monitoring. "The more complex the mobile transport application, the higher the data rate. Our system is specially designed for interference-free data transmission and is compatible with our proven conductor systems such as the U35," explains Dries.

In the event of a power failure, the system is supplied by an emergency generator. Maintenance of the transport system is also easier than before: for example, wear testers indicate in good time when the carbon brushes need to be replaced. This prevents an unintentional shutdown of the ferry operation.

State-of-the-art technology

Up to 100 people and four cars can be carried per trip. The suspended ferry travels at about 5 kilometers per hour and takes 1.5 minutes to cover the approximately 130-meter distance. It shuttles across the canal at 15-minute intervals, even when the water level is low, ice is forming or the current is stronger, and requires less energy than a ferryboat. Since March 2022, both of the city's landmarks - the Rendsburg High Bridge and the floating ferry - are now open again as a single unit for "flowing" traffic in the region. "We are proud to have been involved in the "Schwebefähre 2.0" project to give the city back a piece of its history - authentic like the original, but with technical equipment as befits the traffic of today and tomorrow," Dries sums up. Meanwhile, the municipality is planning to open the next chapter of the "new" landmark: It is to be designated a UNESCO World Heritage Site.